Ngalaba njikwa akụrụngwa, Sinopec Yizheng Chemical Fiber Co., Ltd. 211900

Abstract: Akwụkwọ a na-enyocha ihe ndị na-adịghị mma nke nnukwu turbo expander units, na-ewepụta usoro usoro iji dozie nsogbu ahụ, ma ghọta ihe ize ndụ na ihe mgbochi nke ọrụ.Site na ngwa nke teknụzụ iwepụ varnish, a na-ewepụ ihe egwu zoro ezo na nchekwa dị n'ime unit ahụ.

1. nkọwa

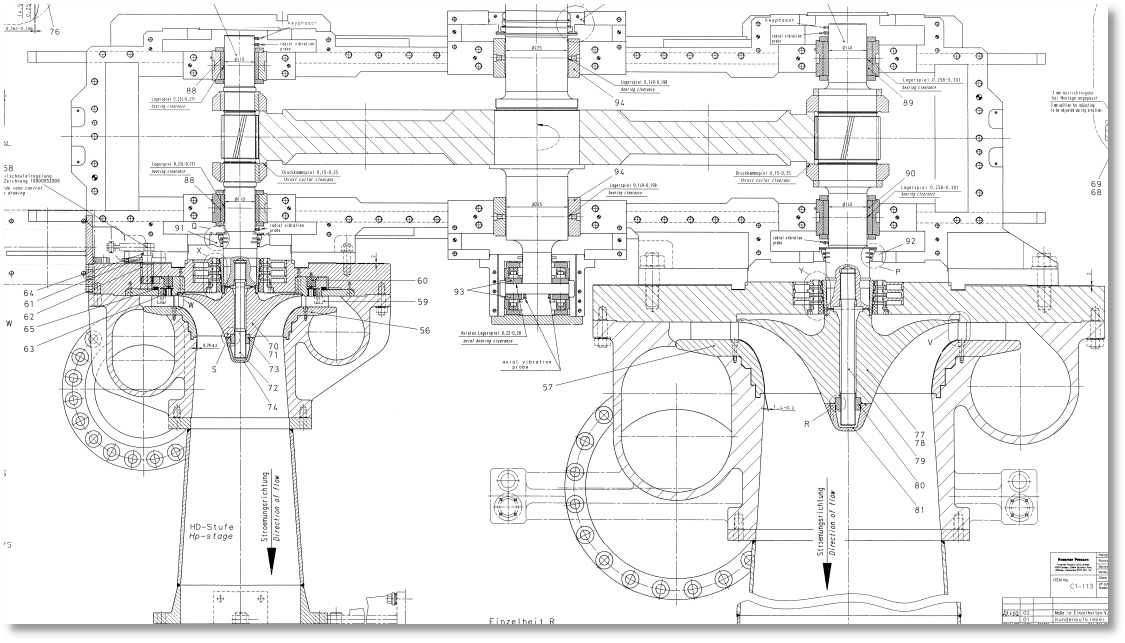

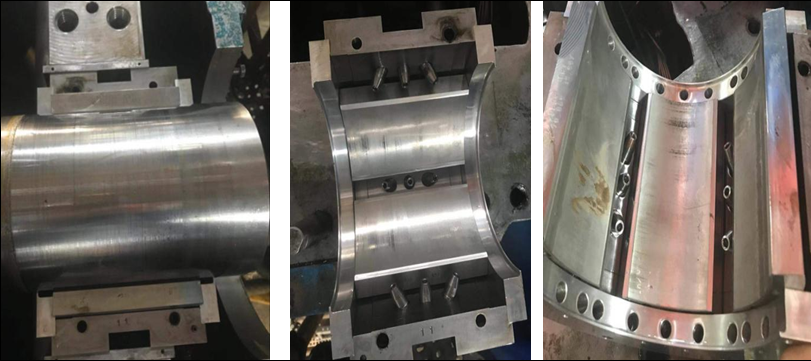

The ikuku compressor unit nke 60 t / a PTA osisi nke Yizheng Chemical Fiber Co., Ltd. na-onwem na ngwá si Germany MAN Turbo.The unit bụ a atọ na otu unit, nke ikuku compressor unit bụ multi-shaft ise-ogbo turbine unit, condensing uzuoku turbine na-eji dị ka isi ụgbọala igwe nke ikuku compressor unit, na turbo expander bụ. eji dị ka ikuku compressor unit.Igwe mbanye inyeaka.Onye na-ebuwanye ibu nke turbo na-anabata mgbasawanye nke ọkwa abụọ dị elu na nke dị ala, nke ọ bụla nwere ọdụ ụgbọ mmiri na ọdụ ụgbọ mmiri na-ekpochapụ, na impeller na-anakwere impeller ụzọ atọ (lee foto 1)

Nleba anya nke ngalaba nke ngalaba mgbasawanye (n'aka ekpe: akụkụ nrụgide dị elu; aka nri: akụkụ nrụgide dị ala)

Isi arụmọrụ nke turbo expander bụ ndị a:

Ọsọ n'akụkụ dị elu dị elu bụ 16583 r / min, na obere nrụgide na-agba ọsọ bụ 9045 r / min;ike zuru oke nke onye na-ebuwanye ibu bụ 7990 KW, na ọnụego erute bụ 12700-150450-kg / h;nrụgide ntinye bụ 1.3Mpa, na ike iyuzucha bụ 0.003Mpa.Okpomọkụ oriri nke akụkụ nrụgide dị elu bụ 175 ° C, na ikpochapu okpomọkụ bụ 80 ° C;oriri okpomọkụ nke akụkụ ala dị ala bụ 175 ° C, na ikpochapu okpomọkụ bụ 45 ° C;A na-eji ihe nkedo tilting mee ihe na nsọtụ abụọ nke elu-nrụgide na nke dị ala n'akụkụ gia shafts Bearings, nke ọ bụla nwere 5 pads, mmanụ ntinye mmanụ nwere ike ịbanye mmanụ n'ụzọ abụọ, na nke ọ bụla nwere otu oghere mmanụ, site na ya. 3 dị iche iche nke 15 mmanụ injection nozzles, dayameta nke mmanụ ntinye mmanụ bụ 1.8mm, E nwere 9 mmanụ nloghachi oghere maka ibu, na n'ọnọdụ nkịtị, 5 ọdụ ụgbọ mmiri na 4 blocks na-eji.Nkeji atọ n'ime otu a na-anabata usoro mmanye mmanye mmanye nke isi na-enye mmanụ site na ọdụ mmanụ mmanụ.

2. Nsogbu na ndị ọrụ

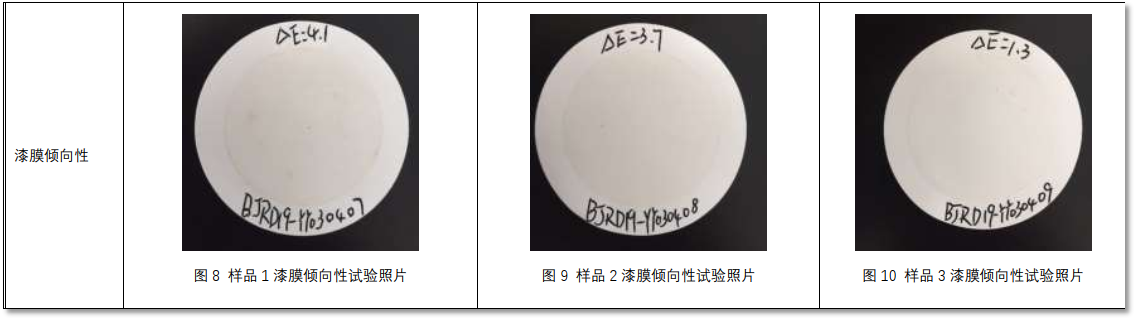

N'afọ 2018, iji mezuo ihe ndị chọrọ ikuku VOC, agbakwunyere otu VOC ọhụrụ na ngwaọrụ ahụ iji gwọọ gas ọdụ nke reactor oxidation, na gas ọdụ ọdụdụ ka na-agbanye n'ime ihe mgbasawanye.N'ihi na nnu bromide dị na gas ọdụ mbụ bụ oxidized na oke okpomọkụ, enwere ion bromide.Iji gbochie ion bromide ka ọ ghara ikpokọta na ikewapụ mgbe gas ọdụ na-agbasa ma na-arụ ọrụ na expander, ọ ga-eme ka corrosion na-emepụta ihe na-ebuwanye ibu na akụrụngwa na-esote.Ya mere, ọ dị mkpa ịbawanye ngalaba mgbasawanye.Okpomọkụ oriri na ikpochapụ okpomọkụ nke akụkụ nrụgide dị elu na akụkụ nrụgide dị ala (lee Tebụl 1).

Tebụl 1 Ndepụta okpomọkụ na-arụ ọrụ na ntinye na ntinye nke mgbasawanye tupu na mgbe mgbanwe VOC gasịrị

| Mba. | Mgbanwe oke | Mgbanwe nke mbụ | Mgbe mgbanwe |

| 1 | Igwe ikuku dị elu n'akụkụ oriri | 175 Celsius C | 190 Celsius C |

| 2 | Okpomọkụ iyuzucha akụkụ dị elu | 80 ℃ | 85 Celsius C |

| 3 | Obere nrụgide akụkụ oriri ikuku okpomọkụ | 175 Celsius C | 195 Celsius C |

| 4 | Obere nrụgide n'akụkụ iyuzucha okpomọkụ | 45 Celsius C | 65 Celsius C |

Tupu mgbanwe VOC, okpomọkụ nke akụkụ na-abụghị impeller na-ebu na njedebe dị ala na-eguzosi ike na ihe dịka 80 ° C (okpomọkụ mkpu nke ebe a bụ 110 ° C, na okpomọkụ dị elu bụ 120 ° C).Mgbe mgbanwe VOC malitere na Jenụwarị 6, 2019, ọnọdụ okpomọkụ nke akụkụ na-abụghị impeller na-ebu na njedebe nrụgide dị ala nke onye na-agbasawanye ji nwayọọ nwayọọ bilie, na okpomọkụ kachasị elu dị nso na okpomọkụ kachasị elu nke 120 ° C, mana paramita vibration agbanwebeghị nke ukwuu n'ime oge a (lee foto 2).

Fig. 2 Eserese nke expander eruba ọnụego na-abụghị ụgbọala n'akụkụ aro ịma jijiji na okpomọkụ

1 - ahịrị eruba 2 - ahịrị njedebe na-adịghị akwọ ụgbọ ala 3 - ahịrị ịma jijiji na-enweghị ụgbọala

3. Ihe kpatara nyocha na usoro ọgwụgwọ

Mgbe ịlele na nyochaa ọnọdụ okpomọkụ mgbanwe mgbanwe nke uzuoku turbine bearings, na ikpochapụ nsogbu nke na-na-saịtị ngosi ngwá ọrụ, usoro mgbanwe, static nnyefe nke uzuoku turbine brush wear, ngwa ngwa fluctuations, na akụkụ àgwà, isi ihe mere na-ebu okpomọkụ fluctuations. bụ:

3.1 Ihe kpatara ịrị elu okpomọkụ nke akụkụ na-abụghị nke impeller na-ebu na njedebe nrụgide dị ala nke mgbasawanye.

3.1.1 Nleba nke disassembly chọpụtara na anya dị n'etiti ihe na-ebu na ogwe aka na nkwụsị nke meshing nke ezé gia bụ ihe nkịtị.Ewezuga varnish a na-enyo enyo n'elu akụkụ na-abụghị nke impeller na njedebe nrụgide dị ala nke onye na-agbasawanye (lee foto 3), ọ dịghị ihe na-adịghị mma a hụrụ na bearings ndị ọzọ.

Onyonyo 3 Foto a na-ahụ anya nke njedebe na-adịghị akwọ ụgbọala na ụzọ kinematic nke mgbasawanye

3.1.2 Ebe ọ bụ na edochiri mmanụ na-agba mmanụ maka ihe na-erughị otu afọ, àgwà mmanụ ahụ agafewo ule tupu ịkwọ ụgbọala.Iji kpochapụ obi abụọ, ụlọ ọrụ ahụ zigara mmanụ mmanu mmanụ na ụlọ ọrụ ọkachamara maka nyocha na nyocha.Ụlọ ọrụ ọkachamara na-akwado na ntinye aka na elu nke na-ebu ibu bụ varnish mbụ, MPC (ntụgharị anya varnish) (lee foto 4)

Ọnụọgụ 4 Akuko nyocha teknụzụ nlekota mmanụ nke teknụzụ ọkachamara na-ahụ maka mmanụ nyere

3.1.3 Mmanụ na-ete mmanụ a na-eji na mgbasawanye bụ Shell Turbo No. 46 mmanụ turbine (mmanụ ịnweta).Mgbe mmanụ ịnweta mmanụ na-ekpo ọkụ na-ekpo ọkụ, mmanụ mmanụ na-eme ka ọ bụrụ oxidized, na ngwaahịa oxidation na-ezukọ n'elu osisi na-ebu ibu iji mepụta varnish.Ihe mejupụtara mmanụ lubricating mineral bụ ihe mejupụtara ya bụ hydrocarbon, nke kwụsiri ike na ụlọ okpomọkụ yana obere okpomọkụ.Otú ọ dị, ọ bụrụ na ụfọdụ (ọbụlagodi ọnụ ọgụgụ dị nnọọ nta) nke molekul hydrocarbon na-enweta mmeghachi omume oxidation na okpomọkụ dị elu, ụmụ irighiri mmiri hydrocarbon ndị ọzọ ga-enwekwa mmeghachi omume nrịanrịa, nke bụ njirimara nke mmeghachi omume hydrocarbon.

3.1.4 Ndị na-ahụ maka ngwá ọrụ na-eme nyocha gburugburu nkwado nke ahụ akụrụngwa, nrụgide oyi nke ntinye na ntinye pipeline, nchọpụta nkwụsị nke usoro mmanụ, na iguzosi ike n'ezi ihe nke nyocha okpomọkụ.Na dochie a set nke bearings na-abụghị mbanye ọgwụgwụ nke ala-nrụgide akụkụ nke expander, ma mgbe ụgbọala maka otu ọnwa, okpomọkụ ka ruru 110 ℃ , na mgbe ahụ, e nwere nnukwu fluctuations na vibration na okpomọkụ.Emere ọtụtụ mgbanwe ka ị bịaruo nso na ọnọdụ ndị a na-emegharịghachi, ma ọ fọrọ nke nta ka ọ bụrụ na-enweghị mmetụta ọ bụla (lee foto 5).

Ọnụọgụ 5 eserese nke ihe nrịbama metụtara ya sitere na February 13 ruo Maachị 29

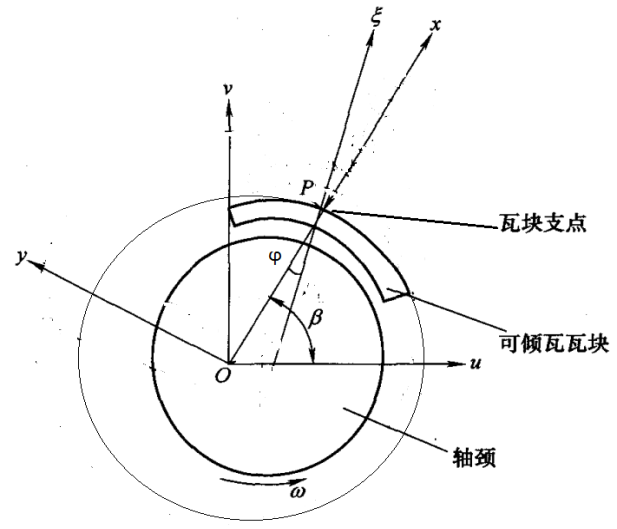

onye na-emepụta MAN Turbo, n'okpuru ọnọdụ ọrụ nke ugbu a nke onye na-ebuwanye ibu, ma ọ bụrụ na ụda ikuku nke oriri na-akwụsi ike na 120 t / h, ike mmepụta bụ 8000kw, nke dị nso na mmepụta mmepụta mbụ nke 7990kw n'okpuru ọnọdụ ọrụ nkịtị;Mgbe olu ikuku bụ 1 30 t / h, ike mmepụta bụ 8680kw;ma ọ bụrụ na oriri ikuku olu bụ 1 46 t / h , mmepụta ike bụ 9660kw.Ebe ọ bụ na ọrụ a na-arụ site n'akụkụ obere nrụgide na-eme ka ụzọ abụọ n'ụzọ atọ nke onye na-emewanyewanyewanye, enwere ike ibufe akụkụ dị ala nke onye na-ebuwanye ibu.Mgbe okpomọkụ gafere 110 Celsius C, uru na-ama jijiji na-agbanwe nke ukwuu, na-egosi na a na-akpụcha varnish ọhụrụ n'elu ogwe osisi na osisi na-ebu ya n'oge a (lee foto 6).

Ọgụgụ 6 Tebụlụ nguzozi ike nke ngalaba mgbasawanye

3.2Nyocha usoro nke nsogbu ndị dị adị

3.2.1 Dị ka e gosiri na Figure 7, a pụrụ ịhụ na akụkụ agụnyere n'etiti ntakịrị ntụziaka vibration nke fulcrum nke ngọngọ tile na ahịrị na-edozi ahụ na nhazi nhazi bụ β, akụkụ ntụgharị nke ngọngọ tile bụ φ , na tilting pad bearing system nke mejupụtara taịlị 5, mgbe taịl ahụ Mgbe a na-etinye pad ahụ na nrụgide ihe nkiri mmanụ, ebe ọ bụ na fulcrum nke pad ahụ abụghị ahụ siri ike zuru oke, ọnọdụ nke fulcrum nke pad mgbe nrụrụ mkpakọ ga-adị. mepụta obere ntugharị n'akụkụ ụzọ geometric preload direction n'ihi isi ike nke fulcrum, si otú ahụ na-agbanwe nkwụsị nke ibu na ọkpụrụkpụ ihe nkiri mmanụ [1]] .

Fig.7 nhazi usoro nke otu mpe mpe akwa nke tilting pad bear

3.2.2 Enwere ike ịhụ ya site na eserese 1 na rotor bụ ihe owuwu cantilever, na impeller bụ akụkụ ọrụ isi.Ebe ọ bụ na akụkụ nke impeller bụ akụkụ nke ịnya ụgbọ ala, mgbe gas na-agbasawanye iji rụọ ọrụ, ọkpụkpụ na-atụgharị n'akụkụ akụkụ nke impeller nọ n'ọnọdụ dị mma na ohia na-ebu ya n'ihi mmetụta nke ikuku gas, na ọdịiche mmanụ na-anọgide na-adị mma.Na usoro nke meshing na-ebufe torque n'etiti nnukwu na obere gia, na nke a dị ka fulcrum, radial free ije nke na-abụghị impeller akụkụ aro ga-ejedebeghị n'okpuru ibu ibu ọnọdụ, na lubricating film mgbali dị elu karịa nke ndị ọzọ. bearings, na-eme ka ebe a lubricated The film stiifness na-abawanye, mmanụ film mmeghari ọnụego mbelata, na frictional okpomọkụ na-abawanye, na-akpata a varnish.

3.2.3 A na-emepụta varnish dị na mmanụ ahụ n'ụdị atọ: mmanụ oxidation, mmanụ "micro-combustion", na mwepu okpomọkụ dị elu nke mpaghara.Ekwesịrị ime varnish ahụ site na "micro-combustion" nke mmanụ.Usoro ahụ bụ nke a: a ga-agbaze ụfọdụ ikuku (n'ozuzu ihe na-erughị 8%) na mmanụ na-agba mmanụ.Mgbe njedebe solubility gafere, ikuku na-abanye na mmanụ ga-adị na mmanụ n'ụdị egosipụta kwụsịtụrụ.Mgbe ị banyere n'úkwù, nnukwu nrụgide na-eme ka afụ ndị a banye ngwa ngwa adiabatic mkpakọ, na mmiri ọkụ na-ebili ngwa ngwa iji mee ka adiabatic "micro-combustion" nke mmanụ, na-ebute oke obere obere insolus.Ihe ndị a na-adịghị ahụkebe bụ pola ma na-agbasochi anya n'elu igwe iji mepụta varnishs.Ka nrụgide dị ukwuu, na-ebelata ihe solubility nke ihe na-adịghị edozi ahụ, ọ na-adịkwa mfe ịmalite ịmalite ma dozie iji mepụta varnish.

3.2.4 Site na nhazi nke varnish, ọkpụrụkpụ nke ihe nkiri mmanụ na steeti na-enweghị nnwere onwe na-eji varnish, n'otu oge ahụ ọsọ ọsọ nke ihe nkiri mmanụ na-ebelata, na okpomọkụ na-ebili nwayọọ nwayọọ, nke na-abawanye. esemokwu dị n'etiti elu nke ohia na-ebu na ogwe osisi, na varnish na-edobe na-akpata nkwụsị ọkụ na-adịghị mma na mmụba mmanụ ọkụ na-eduga n'ịdị elu nke oke ohia.N'ikpeazụ, akwụkwọ akụkọ ahụ na-agbanye na varnish, bụ nke a na-egosipụta na mgbanwe ime ihe ike na ụda olu.

3.2.5 Ọ bụ ezie na ọnụ ahịa MPC nke mmanụ na-ebuwanye ibu adịghị elu, mgbe e nwere varnish na usoro mmanụ mmanụ, mgbasa na mmiri ozuzo nke ihe ndị dị na varnish na mmanụ na-ejedebe n'ihi oke ikike nke mmanụ na-agbaze mmanụ. akụkụ nke varnish.Ọ bụ usoro nguzozi dị ike.Mgbe ọ rutere n'ọnọdụ zuru oke, varnish ga-ekwado n'elu ihe mkpuchi ma ọ bụ ihe eji eme ihe, na-eme ka mgbanwe okpomọkụ nke ihe mkpuchi ahụ, nke bụ nnukwu ihe ize ndụ zoro ezo na-emetụta ọrụ nchekwa.Ma n'ihi na ọ na-agbaso na pad na-ebu ibu, ọ bụ otu n'ime ihe kpatara mmụba okpomọkụ nke ihe mkpuchi ahụ.

4 Usoro na ihe mgbochi

Ịwepụ nchịkọta nke varnish na nkedo nwere ike hụ na ibu nke unit na-agba ọsọ na okpomọkụ a na-achịkwa.Site na nyocha na nkwurịta okwu na ọtụtụ ndị na-emepụta ngwá ọrụ na-ewepu varnish, anyị họọrọ Kunshan Winsonda, nke nwere mmetụta dị mma na aha ahịa, iji mepụta WVD-II electrostatic adsorption + resin adsorption, nke bụ ngwá ọrụ na-ewepu varnish na-ewepụ agba.akpụkpọ ahụ.

WVD-II usoro mmanụ na-asachapụ nke ọma na-ejikọta teknụzụ mgbasa ozi mgbasa ozi electrostatic na teknụzụ mgbanwe ion, dozie varnish gbazere site na mgbasa ozi resin, wee dozie varnish agbagoro agbagoro site na mgbasa ozi electrostatic.Teknụzụ a nwere ike ibelata ọdịnaya nke sludge n'ime obere oge , N'ime obere oge nke ọtụtụ ụbọchị, usoro lubrication mbụ nwere nnukwu sludge / varnish nwere ike iweghachi ya na steeti kacha mma na-arụ ọrụ, yana nsogbu nke ngwa ngwa ịrị elu. Enwere ike idozi ọnọdụ okpomọkụ nke mkpali nke varnish kpatara.Ọ nwere ike wepụ nke ọma ma gbochie sludge mmanụ soluble na nke na-abụghị nke a na-emepụta n'oge arụ ọrụ nkịtị nke turbine uzuoku.

Isi ụkpụrụ ya bụ ndị a:

4.1 ion resin mgbanwe iji wepụ varnish agbazere

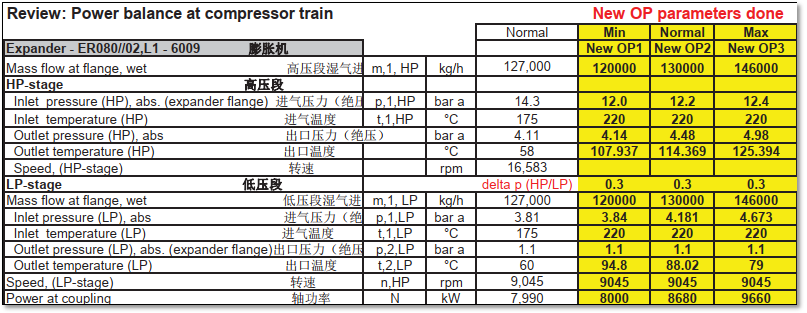

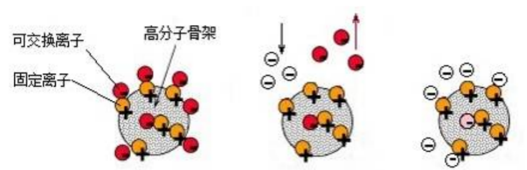

Ion mgbanwe resin bụ tumadi mejupụtara abụọ akụkụ: polymer skeleton na ion mgbanwe otu.E gosipụtara ụkpụrụ adsorption na foto 8,

Ọgụgụ 8 Ụkpụrụ nke ion-interaction resin adsorption

A na-ekewa otu mgbanwe ahụ n'ime akụkụ edozi na akụkụ nke mbughari.Akụkụ ahụ edoziri na-ejikọta na matrix polymer na enweghị ike ịmegharị n'efu, wee ghọọ ion edozi;A na-ejikọta akụkụ a na-ebugharị na akụkụ nke edoziri site na njikọ ionic ka ọ bụrụ ion mgbanwe.Ion ndị etinyere na ion mkpanaka nwere ụgwọ dị iche iche n'otu n'otu.N'ebe ohia na-ebu ibu, akụkụ mkpanaka ahụ na-abanye n'ime ions na-agagharị agagharị, nke na-agbanwe na ngwaahịa ndị ọzọ na-emebi emebi na otu ụgwọ ahụ, nke mere na ha na-ejikọta ya na ion ndị a na-edozi ma na-agbanyesi ike na ntọala mgbanwe.Na otu ahụ, a na-ewepụ ya site na mmanụ, gbazere varnish wepụrụ site na ion mgbanwe resin adsorption.

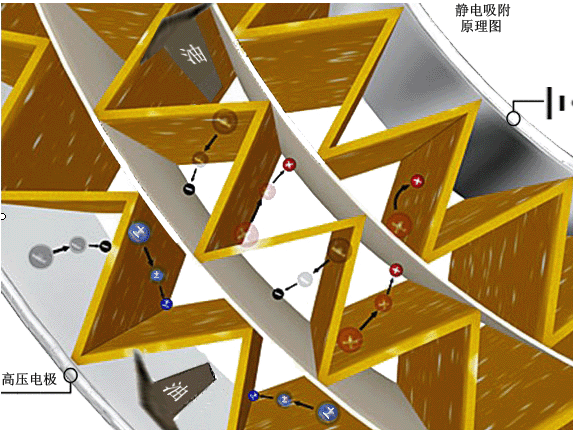

4.2 Teknụzụ mgbasa ozi electrostatic iji wepụ varnish kwụsịtụrụ

Teknụzụ mgbasa ozi electrostatic na-ejikarị igwe na-ebupụta voltaji dị elu na-emepụta mpaghara ọkụ eletrik dị elu iji mee ka ihe ndị e merụrụ emerụ dị na mmanụ ahụ gosi ebubo dị mma na nke na-adịghị mma n'otu n'otu.A na-agbanye ihe ndị ahụ na-anọpụ iche ma na-emegharị ya site na ihe ndị ahụ ebubo, na n'ikpeazụ, a na-ejikọta ihe niile ahụ ma tinye ya na onye nchịkọta (lee foto 9).

Ọgụgụ 8 Ụkpụrụ nke teknụzụ mgbasa ozi electrostatic

Teknụzụ ihicha mmanụ electrostatic nwere ike wepu ihe mmetọ niile na-adịghị edozi, gụnyere adịghị ọcha na varnish kwụsịtụrụ nke mmebi mmanụ mepụtara.Agbanyeghị, ihe nzacha ọdịnala nwere ike wepu naanị oke irighiri ihe nwere nkenke dabara adaba, ọ na-esikwa ike iwepu submicron. larịị kwụsịtụrụ varnish .

Usoro a nwere ike dozie kpamkpam varnish precipitated na-edebe na-ebu na mpe mpe akwa, si otú kpamkpam na-edozi mmetụta nke na-ebu pad okpomọkụ na vibration mgbanwe nke varnish kpatara, nke mere na unit nwere ike na-agba ọsọ kwụsie ike ruo ogologo oge.

5 Nkwubi okwu

WSD WVD-II varnish wepụrụ unit etinyere n'ọrụ, site na afọ abụọ nke nyocha ọrụ, a na-edobe okpomọkụ na-ebu ya mgbe niile na gburugburu 90 Celsius, na unit ahụ ka na-arụ ọrụ nkịtị.A chọtara ihe nkiri varnish (lee foto 10).

Foto a na-ahụ anya nke na-ebu disassembly mgbe ị wụnye varnish mwepụ

akụrụngwa

ntụaka:

[1] Liu Siyong, Xiao Zhonghui, Yan Zhiyong, na Chen Zhujie.Simulation ọnụọgụ na nyocha nnwale gbasara njirimara ike nke pivot elastic na damping tilting pad bearings [J].Akwụkwọ akụkọ Chinese nke Mechanical Engineering, October 2014, 50(19):88.

Oge nzipu: Dec-13-2022